Frequency and servo inverters for control cabinet installation

Inverters for control cabinet installation are designed for IP20 and IP31 degrees of protection. The devices can be installed with zero clearance in the control cabinet to save space. In a power range from 0.34 to 147 hp (0.25 to 110 kW) and for a line voltage connection to 1 x 230 V (up to 3.0 hp (2.2 kW)), 3 x 230 V (up to 7.4 hp (5.5 kW)) or 3 x 400/480 V, the devices are available in a compact design. Thus, network topologies can be clearly arranged even in the smallest places. All other control components, such as the controller and the I/O system, are mounted right next to the frequency inverters and servo inverters

Flexible – FAST – Future-proof

The i950 is the basis of a compact servo drive that integrates consistently into our automation platform with absolute ease. The same architecture, the same engineering and use of the same application software dissolve the boundaries between drive-based and controller-based automation. The “FAST” application software toolbox becomes usable for all products. With FAST, we make a lot of things easier for the customer as the FAST applications of the i950 can be put to use immediately and can be adapted to the respective machine task by means of parameterization alone. If necessary, however, they can be adapted and extended very easily according to specific customer requirements. In addition, the i950 servo inverter enhances the performance of the i700 servo inverter in our controller-based system in the range of 30 to 148 hp (22 to 110 kW).Your advantages:

- One platform, flexibly scalable: The i950 is the completing element of a coherent Lenze automation platform for modular machine solutions, flexibly scalable from the smallest machine module with only one motion axis to complex multi-axis systems.

- FAST applications, usable immediately: The i950 comes with FAST “Inside” technology applications, which can be selected very easily by means of the EASY Starter and used immediately.

- Future-proof and ready for Industry 4.0: Due to open standards, such as PLCopen, IEC61131-3, and CIA402, we make it possible for the OEM to repeatedly re-use already completed engineering work for different applications, today and in the future.

- Compact design: All versions of the i950 have a very compact design and, up to 20 hp (15 kW), can be integrated into 9.84 in (250 mm)-deep control cabinets.

i550 frequency inverters

The frequency inverters of the i510 and i550 series support a power range from 0.34 to 177 hp (0.25 to 132 kW). The basic i510 inverter covers a power range from 0.34 to 20 hp (0.25 to 15 kW) and the universally applicable i550 which enables communication via all common fieldbuses covers a power range from 0.34 to 177 hp (0.25 to 132 kW).Both devices offer the following distinguishing features:

- Slimline design from 2.36 x 5.12 in (60 mm x 130 mm): fits into every control cabinet

- Scalable functionality thanks to their modular system

- Exceptional user-friendliness

All advantages of the frequency inverter i550 at a glance:

| Performance data: | Line voltage: 1 AC 120 V: 0.34 to 1.5 hp (0.25 to 1.1 kW)Line voltage: 1 AC 230 V: 0.34 to 3.0 hp (0.25 to 2.2 kW)Line voltage: 1/3 AC 230 V: 0.34 to 7.4 hp (0.25 to 5.5 kW)Line voltage: 3 AC 400 V: 0.50 to 177 hp (0.37 to 132 kW) |

| Integrated functions: | V/f controls (linear, quadratic)Braking energy managementEnergy-saving function “VFCeco”Sensorless vector control for asynchronous and synchronous motorsServo control for asynchronous motorsSpeed feedback (HTL encoder) |

| Communication: | CANopen, EtherCAT, EtherNet/IP, I/O link, Modbus, PROFIBUS, PROFINET, ModbusTCP/IP, POWERLINK |

| Approvals: | CE, UL, CSA, EAC, RoHS2, IE2 in accordance with EN 50598-2 |

| Efficiency class: | Top efficiency class for inverters with IE2 in accordance with EN 50598-2 |

| Safety technology: | Safe torque off (STO) |

i700 servo inverters

Generation Easy for multi-axis applications

i700 servo inverters for controlled, dynamic motion.Performance data of supply modules:

- Line voltage: 3 AC 400/480 V

Performance data of axis modules:

- Single axis: 1.0 to 20 hp (0.75 to 15 kW) / 2.5 to 32 A

- Multi axis: 1.0 to 10 hp (0.75 to 7.5 kW) / 2.5 to 16 A

Advantages:

- Connections: digital inputs/outputs (2/0)

- Resolver and encoder feedback

- Communication: EtherCAT

- Axis modules capable of multiple overloads for peak output currents between 5 and 64 A, double axes up to 32 A

- The servo inverter for Controller-based Automation in conjunction with the various types of Controllers

- CIA 402 operating modes (position, velocity, torque-control, velocity-mode)

- STO safety function

9400 servo inverters

Impressive results for demanding machine tasks and single-axis or multi-axis applications

9400 HighLine servo inverters for controlled, dynamic motion.Performance data:

- Single Drives: 0.50 to 321 hp (0.37 to 240 kW) / 1.5 to 460 A

- Multi Drives: 0.50 to 40 hp (0.37 to 30 kW) / 1.5 to 59 A

Advantages:

- Connections: start/stop, analog inputs/outputs (2/2), freely programmable digital inputs/outputs (8/4)

- Resolver and universal multi-encoder input

- Communication: CANopen, DeviceNet, EtherCAT, Ethernet, EtherNet/IP, POWERLINK, PROFIBUS, PROFINET

- Supports synchronous and asynchronous motors

- Integrated brake management

- Scalable memory thanks to multiple memory modules

- Versatile and freely configurable technology functions, e.g. for table positioning, positioning controls, electronic gearboxes and cams

- Scalable safety functions

8400 TopLine frequency inverters

Easily achieve high dynamic performance and precision

8400 TopLine frequency inverters for controlled, dynamic motion.Performance data:

- Line voltage: 1 AC 230/240 V: 0.34 to 3.0 hp (0.25 to 2.2 kW) / 1.7 to 9.5 A

- Line voltage: 3 AC 400/500 V: 0.50 to 60 hp (0.37 to 45 kW) / 1.0 to 89 A

Advantages:

- Connections: start/stop, analog inputs/outputs (2/2), freely programmable digital inputs/outputs (7/4)

- Resolver and multi-encoder input

- Communication: CANopen on board, EtherCAT, EtherNet/IP, POWERLINK, PROFIBUS, PROFINET

- Supports synchronous motors

- Axis bus for electrical shafts

- Integrated brake management

- “VFC eco” energy-saving function

- STO safety function

8400 HighLine frequency inverters

Help you stay on top of the situation

8400 HighLine frequency inverters for easily controlled motion and positioning.Performance data:

- Line voltage: 1 AC 230/240 V: 0.34 to 3.0 hp (0.25 to 2.2 kW) / 1.7 to 9.5 A

- Line voltage: 3 AC 400/500 V: 0.50 to 60 hp (0.37 to 45 kW) / 1.0 to 89 A

Advantages:

- Connections: start/stop, analog inputs/outputs (2/2), freely programmable digital inputs/outputs (7/4)

- Communication: CANopen on board, EtherCAT, EtherNet/IP, POWERLINK, PROFIBUS, PROFINET

- Suitable for drive applications with or without speed feedback

- Integrated positioning control

- Up to 15 selectable positioning points included for each of the corresponding travel profiles

- Integrated brake management

- “VFC eco” energy-saving function

- STO safety function

EC dual-use regulation

What is the EC dual-use regulation?

The EC dual-use regulation (Regulation (EC) No. 428/2009) is an instrument applied by the European Community to control the export of goods, including data processing programs and technologies, that can be used for dual purposes. The Regulation defines the term “dual use” items as referring to goods that can be used for both civilian and military purposes. Annex I of the EC Dual Use Regulation contains a list of the goods that it is not permissible to export to another country unless prior authorization to do so has been obtained.What changes are there and what does this mean for the export of frequency converters?

The technical characteristics relevant to the export of frequency converters (Lenze calls them inverters) are indicated in No. 3A225 of Annex I of the aforementioned regulation. As a consequence of the changes in the technical characteristics specified there, the export controls for inverters have been expanded. This means that export authorization now has to be obtained for inverters that could previously be exported without authorization.How do I know whether the export of an inverter requires prior authorization?

If the export of a Lenze inverter requires prior authorization, Lenze indicates this on all relevant business papers and documents (offers, order papers, delivery papers etc.) by noting the following: “Product requiring export authorization when shipping to countries outside the EC – Export List No. 3A225 (EC Dual Use Regulation)”Is the availability of Lenze inverters restricted due to the changes in the regulation?

No. Where Lenze exports affected products into countries outside the EC, we perform all the necessary procedures and arrange for the required export authorization, thus ensuring availability of the products. Therefore, there is no change in the availability of inverters.Does export authorization also have to be obtained for inverters that are built into another product/machine?

No, for the vast majority of applications this is not the case. The question of whether the inverter can be considered the principal element of the application plays the key role in this context. In judging whether the inverter is to be considered the principal element, it is necessary to weigh the factors of quantity, value and technological know-how involved and other special circumstances which might establish the inverter as the principal element of the machine it is built into. In any case, every exporter is obliged to independently check whether export authorization is required.What customs tariff number do Lenze inverters have?

The customs tariff number for Lenze inverters is 85044090What do I have to do if I want to export a Lenze inverter to another country?

- Delivery within the European Union: For shipments within the EC, no export authorization is required. The requirement to obtain export authorization for the product in the case of an export outside the EC must however be indicated on all relevant business papers.

- Depending on the final destination of the product to be exported, general export authorizations (e.g. EU 001) can be used in some cases. The exact rules depend on the EU country from which you want to export the inverter. This is because implementation of the EC dual-use regulation varies from country to country. Please contact the responsible authorities to obtain the relevant information.

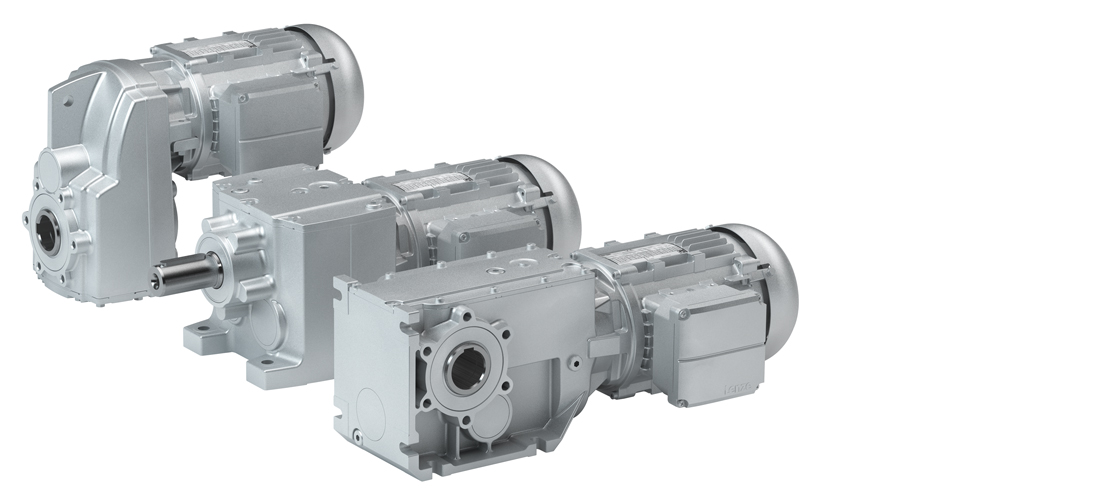

Gearboxes: robust power packages

One single motor alone is not a universal solution to all applications. After all, many applications require low speed and high torque, and your machine may need a right-angle drive.

The robust, efficient gearboxes and geared motors from Lenze can handle even the toughest of machine tasks here.

And if you require couplings, locking bushes or other drive elements for your machine, you are sure to find precisely the right products for your requirements in the scalable product portfolio from Lenze Selection.

Previous versions – frequency and servo inverters

Tried-and-tested inverter and servo drives

The previous version frequency and servo inverter products have been installed in countless series machines around the world. In them they ensure that your machines and equipment run trouble-free at the high quality level you have come to appreciate from Lenze products.

Are you interested in learning more about these products? Click here to find more details about our tried-and-tested previous version products.

Servo Inverters for control cabinet installation

- ECS series servo inverters

- 9300 series servo inverters

- 9300 PLC servo inverters

Frequency Inverters for control cabinet installation

- 9300 vector frequency inverters

- 8200 vector frequency inverters

- SMD series frequency inverters

Frequency Inverters for motor-mounting or decentral mounting

- 8200 motec frequency inverters with protection class up to IP65

- LCU series motor controllers with protection class up to IP54

- OCU series motor controllers with protection class up to IP54

- ICU series motor controllers with protection class up to IP54

Lenze software

Software plays an ever increasing role in machine functionality.

A digitised development process makes it possible to conduct more precise iterations at an earlier phase in the project, provides support for programming the application software and paves the way towards virtual commissioning.

The main advantages for you are shorter development cycles with fewer staff and faster time-to-market.